Melt-Manager Control Systems

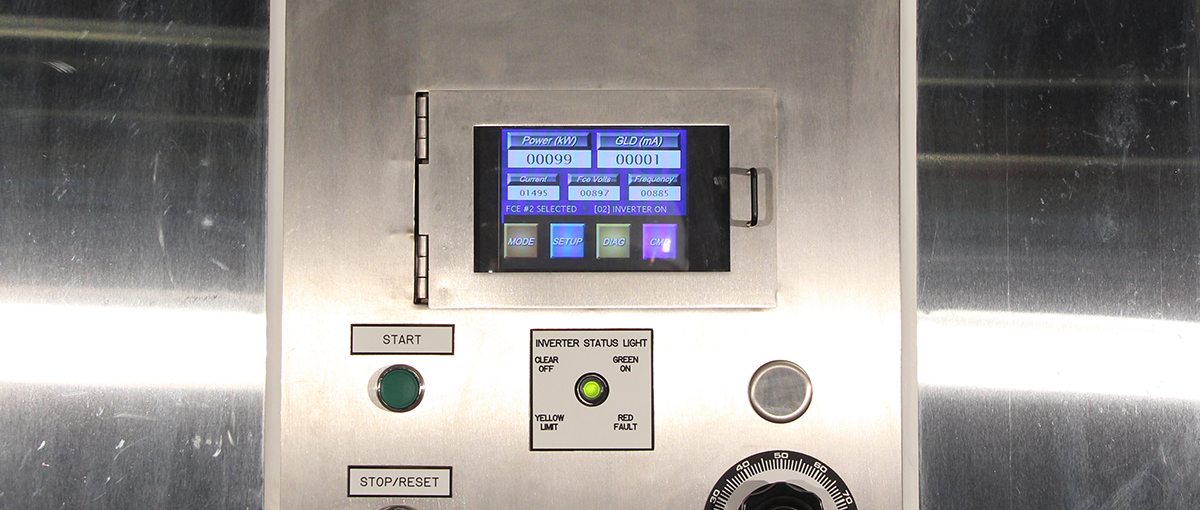

Melt-Manager™ Control Systems are our entry level to smart systems that utilize embedded microprocessor controls and provide the operator with melt control modes and diagnostics for analysis and support.

Features

Melt-Manager™ Control Systems integrate a color touch-screen LCD display that provides direct access to inverter information and controls, including:

- Melt Control Modes: The kilowatt hour melting feature allows the operator to input a kilowatt hours per ton and furnace weight to calculate the kilowatt hours needed to reach pouring temperature. This also provides a safety hold power feature which maintains a furnace bath temperature when the kilowatt hour count is complete.

- Preheat Controls: The automatic cold start feature allows the operator to input a heating schedule to preheat the furnace lining to reduce manpower requirements and production efficiency. The sintering feature also improves long lining life by allowing the operator to input a heating profile to automate the sinter control process.

- Easy-to-access Diagnostics: Provides main display of equipment meters, alarms and event information with a color-coded status. The furnace inductance calculation feature can aid the operator in determining the furnace lining condition.

Tech Specs

| Standard Features | Operator-friendly, Color Touch-Screen LCD Display | |

| Embedded Microprocessor Control | ||

| Displays and Records the Power Supply Meter Readings | ||

| Displays Color Coded System Events and Alarms | ||

| Displays Melt Control Operating Status | ||

| Automated Control of the Complete Melt Cycle | ||

| Schedule Input for Automated Cold Start Control | ||

| Permits Heating Profile Input for Automatic Lining Sintering | ||

| Calculates Furnace Inductance | ||

| Comprehensive Diagnostic Checks | ||

| Provides Event Information Associated with Incoming AC Line Voltage | ||

| Provides Event Information to Alert Users to Potential Arcing Situations | ||

| Includes Built-In Safety Features to Maintain Proper Operation | ||

| Displays Total Kilowatt Hours Used | ||

| Demand Control Input Option | ||

| Auxiliary/Temperature Control Input Option | ||

| Events History Screen with Date and Time Stamp | ||

| One-Touch Large Meter Display | ||

| Meter Data History Charts | ||

| USB Drive Data Logging | ||

| One-Screen Multi-Language Support | ||

| Factory Tested | Critical Components | |