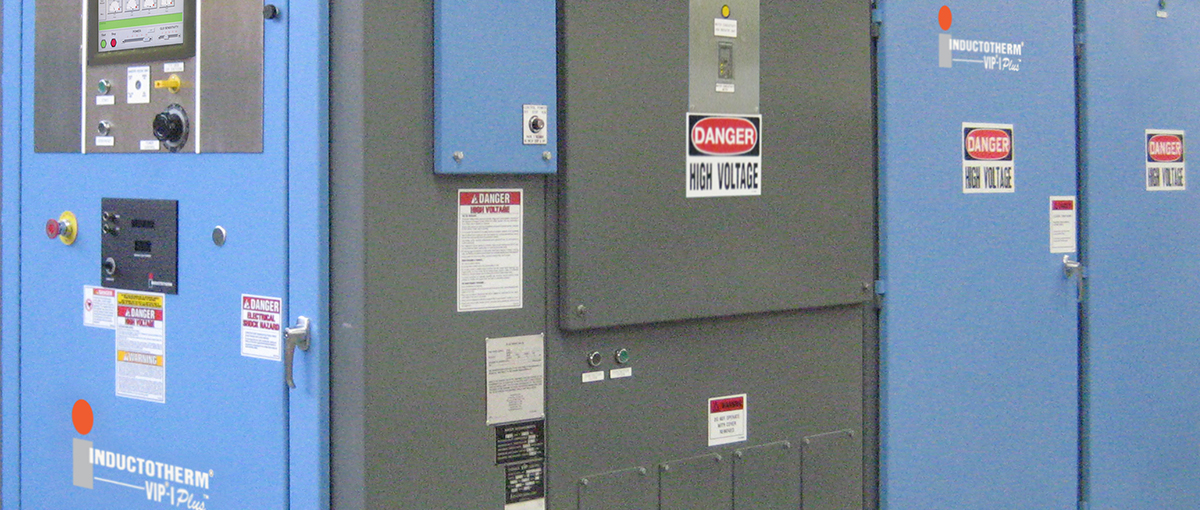

VIP-I Plus Power Supply Units

Both our original VIP™-I™ Power Supply Units and the new VIP™-I™ Plus™ Power Supply Units are suitable for a wide variety of furnace sizes, alloys and offer metal casters reliability, efficiency and guaranteed melt rates in a compact and versatile package. VIP™-I™ Plus™ Power Supply Units enhance our already proven VIP™-I™ Power Supply Units and allow for even greater flexibility.

FEATURES

VIP™-I™ Plus™ Power Supply Units offer the most advanced melting technology and are the leaders for their respective applications, which are based on the power rating required. While VIP™-I™ Power Supply Units are available in a wide range of power levels up to 750 kilowatts, VIP™-I™ Plus™ Power Supply Units can achieve power levels even higher. The units can be fully configured with a variety of options. Standard features include: advanced IGBT power components, husky copper bus bars, precise and responsive digital controls and informative diagnostics. In a standard configuration, these units also include an intelligent digital control board with fiber-optic clear signal processing and a touch-screen display for control and data entry.

| Power Ranges | 1,000 Kilowatts up to 12 Megawatts |

| Contact Inductotherm for Custom Solutions | |

| Standard Features | IGBT Power Components |

| Precise and Responsive Digital Controls | |

| Digital Control Board with Fiber-Optic Clear Signal Processing | |

| Touch-Screen Display for Control and Data Entry | |

| Built-In Ground and Leak Detector System | |

| 6, 12, 24 or 48 Pulse Line Power Rectifier System | |

| Informative Diagnostics | |

| Power Control Adjustable at all Power Levels, Manual or Automatic | |

| Optional Features | System Status Text Messaging |

| Melt-Manager™ Plus™ Control Systems | |

| Factory Tested | Critical Components |

CONTROL OPTIONS

The Melting Room Control allows you to monitor melting, diagnose faults, maximize power usage, minimize power/fuel, and perform a variety of tasks. We offer a variety of control system options including:

- Melting – Management ™ control device is the entry of our intelligence system that uses an embedded microprocessor control and provides the operator with melting control diagnostic mode of analysis and support.

- Melting – Management ™ Plus ™ control devices provide a higher level of automation Support melting melting melting Lv control, diagnostic analysis and customer network, and communication interfaces for the computer application.

- MeltminderTM 300TM Melting Room Control and Management Equipment provides the highest level of automated melting technology to support precision, high responsive and fully programmable control, which is important for the safe and efficient operation of today’s induction melting equipment