iSense™ Systems

iSense™ Melt Shop Equipment Data Visualization Systems bring your equipment together like never before – providing digital content at your fingertips.

Bringing Industry 4.0 Closer to You

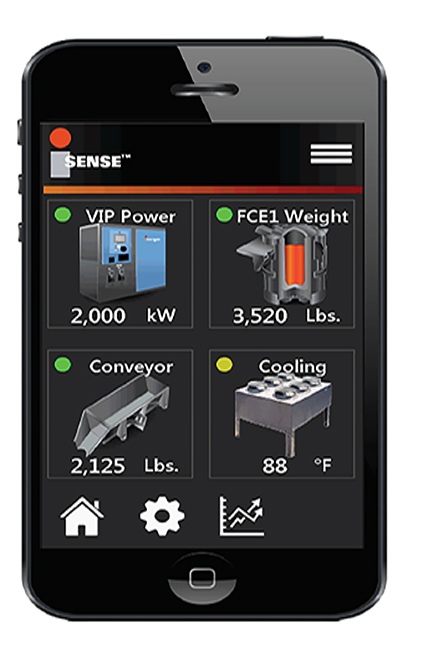

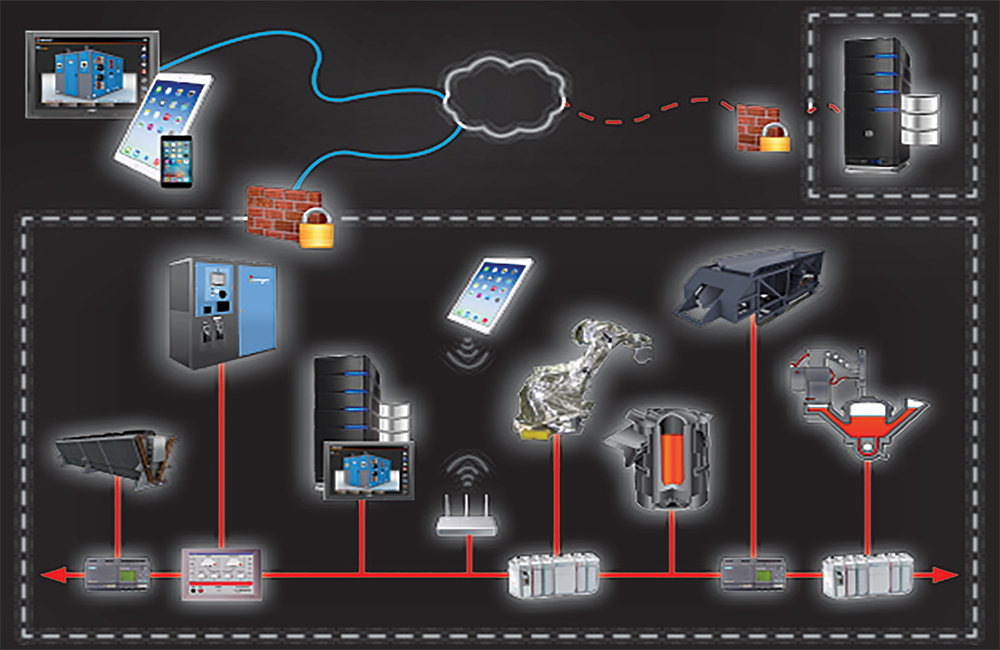

The Inductotherm iSense™ System brings Industry 4.0 closer to your melt shop via Ethernet using standard industrial protocols where network servers collect, store and distribute the equipment data. The application server provides client access for workstations, mobile phones and wireless tablets using a common web-based interface and common browsers. The iSense™ System’s server lives at your location, which keeps data secure and accessible through web clients. Simply provide a Virtual Private Network (VPN) and allow your staff to monitor equipment from anywhere, anytime on the secure network.

Features

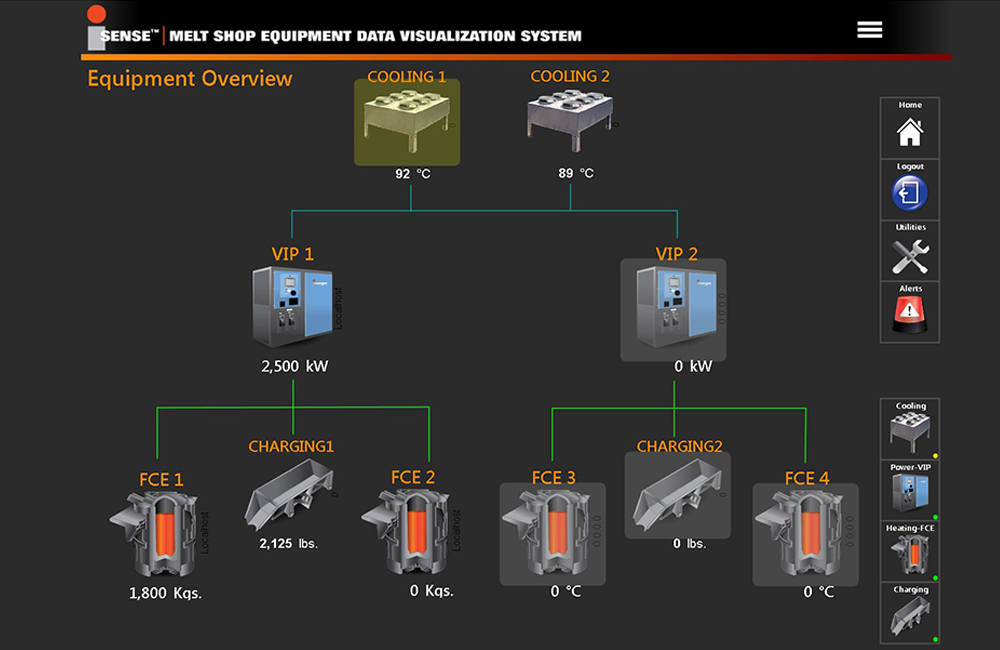

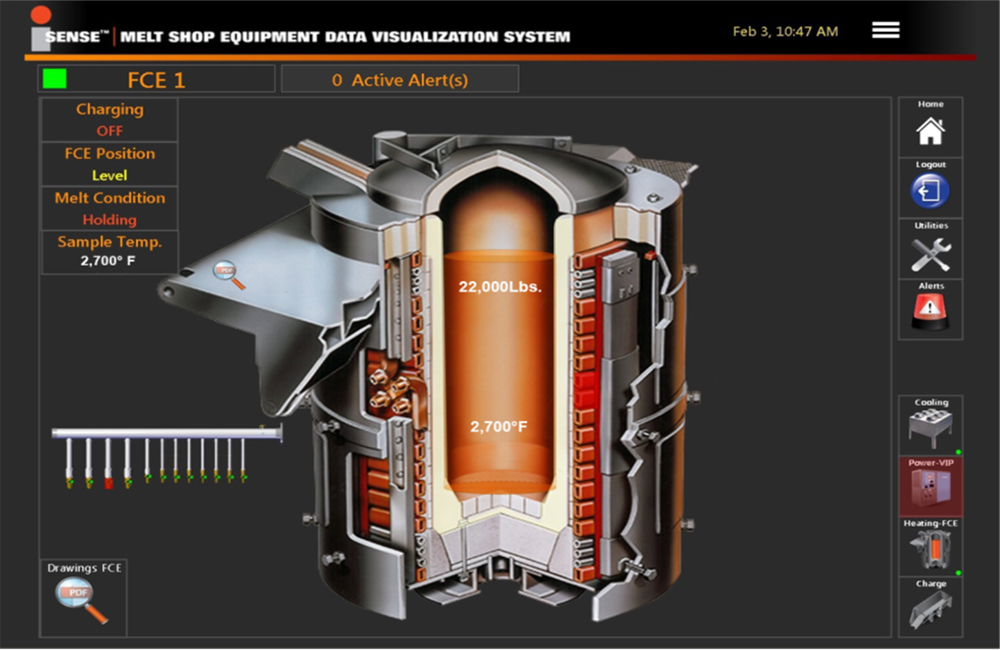

This technology is the only application on the market today that allows you to access nearly every detail of your induction melting equipment in one place — accessible anytime, anywhere. You can see your melt shop overview and relevant data with ease using Inductotherm’s virtual view. Each piece of Inductotherm’s technologically advanced equipment is visually represented with in-depth and color coded information. These colorful graphics show your equipment’s health status and provide access to diagnostics, historical trends and analytics. Watch live events, alarms and conditions unfold before your eyes with interactive graphics and switch between multiple furnaces and equipment with a single touch.

The iSense™ System offers the following benefits:

- Real time data over network media

- Complete networking of Inductotherm equipment

- Detailed equipment data and information access

- Graphical equipment visualization and interaction

- Equipment data management

- Remote access and monitoring

- Customer access to database

Tech Specs

All relevant data in one place:

Inductotherm’s iSense™ Systems include parts lists, equipment drawings, service instructions and other documents. Touch virtually any Inductotherm equipment icon to visualize and expand each piece. View data, important alerts, spare parts lists, drawings, manuals and more. Inductotherm spare parts lists are included for each piece of equipment with the associated part numbers for faster replacement.

One complete data source:

Any Inductotherm equipment capable of communicating over industrial protocols can be tied to the iSense™ System. This includes PLCs, computers, control boards, conductivity meters and advanced sensors including digital temperature sensors, capacitor pressure sensors and inverter signal analysis.

Using the iSense™ System’s main screen your equipment status is shown and you can:

- check your cooling system’s temperature data and fan status

- easily view the relevant data of the VIP® power supply

- “drill down” into detailed information about your control boards and more using a virtual graphic interface.

The integral database holds the complete source of all the information for your system with historical data for data trending charts, alert history (including time stamps), configuration information, parts lists, drawings and other equipment information.

Data is stored for the life of the equipment with the history at your fingertips. Easily identify what data you want to see and within what time frame. Immediate access to intuitive technology creates an easier and more user-friendly experience.