Processes

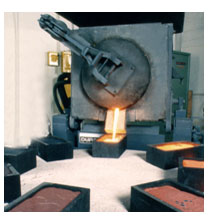

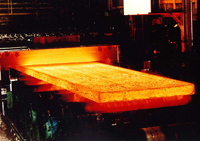

For most metals, melting is the first step in producing a useful product. Inductotherm is the leading manufacturer of induction melting systems and most recognized name in foundries today. We provide a variety of furnace types and capacities — from coffee-cup-size units for melting precious metals to furnaces holding hundreds of tons of iron — for productively melting a full range of ferrous and nonferrous metals.

From state-of-the-art charging and preheating units, through computer controlled induction melting systems available with push-out linings, to high-production automated pouring equipment, Inductotherm technology means fast melt rates, energy efficiency, low metal loss and precise temperature control for optimum metal quality. All of these and more enable Inductotherm to build the ideal melting or heating system for your application.

Inductotherm is involved in many applications. Whether your metal is ferrous or nonferrous, Inductotherm brings advanced technology to your application and to your entire melting or heating operation. No matter what your application, we give you the competitive edge. We give you the competitive edge by providing you with the best customer service, quality and reliability, value, design and technology.