Induction Heating for the Steel Industry

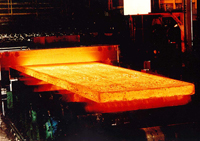

Before a single slab, bloom, bar or billet moves from the continuous caster to the rolling mill, it must be reheated.

Inductotherm induction mass heating systems for bars, blooms, billets, plate, strip and slabs are used prior to rolling operations. Temperature control and consistency are maintained from the surface to the core and over the length of the product. These compact heaters use the high efficiency power units.

Providing the rolling mill with a continuous supply of uniformly heated steel slabs, billets, bars and blooms at the proper temperature is crucial to efficient mill operations. Inductotherm reheating systems include the world’s largest and most technically advanced induction reheaters, before rolling or before gas-fired soaking furnaces.

For coating steel strip, Inductotherm brings the world’s most advanced induction technology to the coating line. “Doorless” coils provide rapid heating, shortening the line. Coreless and channel coating pots hold metal with minimal power and premelt furnaces provide a continuous supply of metal to the line.