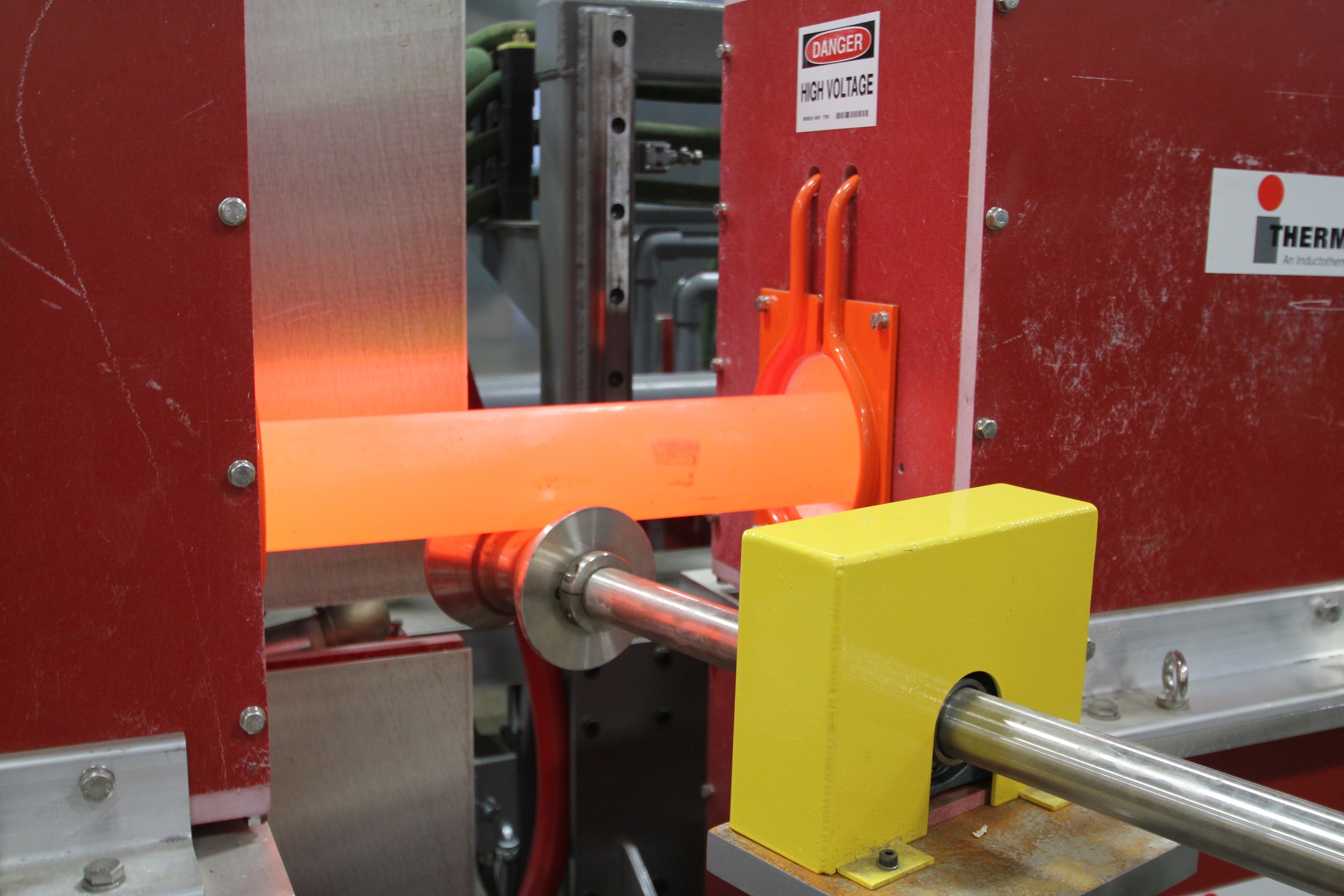

Full Body Annealers

Thermatool™ Full Body Annealers support both in-line and off-line solid-state induction heating of many different varieties of tube, pipe, and bar. Precise induction heating, like that provided by Thermatool™ Full Body Annealers, is critical for post-processing applications such as paint curing or bending operations for small and large diameter pipe.

Applications

Applications for in-line full body heating systems include:

- Preheat for inline painting/UV coating

- Induction heating of tube prior to the galvanizing process. This is typically carried out at medium frequency (10 kHz). Galvanization may be required on both the inner and outer tube surface, hence the need for heat to penetrate throughout

- Annealing of condenser /refrigeration tube at mill speeds up to 150 m/min. The 150 kHz annealing process enables this type of tubing to be coiled prior to use

- Annealing of automotive brake line tubing is also carried out at around 150kHz. Annealing not only gives radial strength to the tube, facilitating high pressure containment, but it also enables tubing to be efficiently coiled prior to installation

Applications for off-line full body heating systems include:

- Normalizing and stress relieving for bar and heavy wall product

- Upset end pre-heating for drill casing

Tech Specs

Power Ratings: 50 kW – 2000 kW

Operating Frequency: 150 Hz – 3 kHz (each)