Seam Annealers

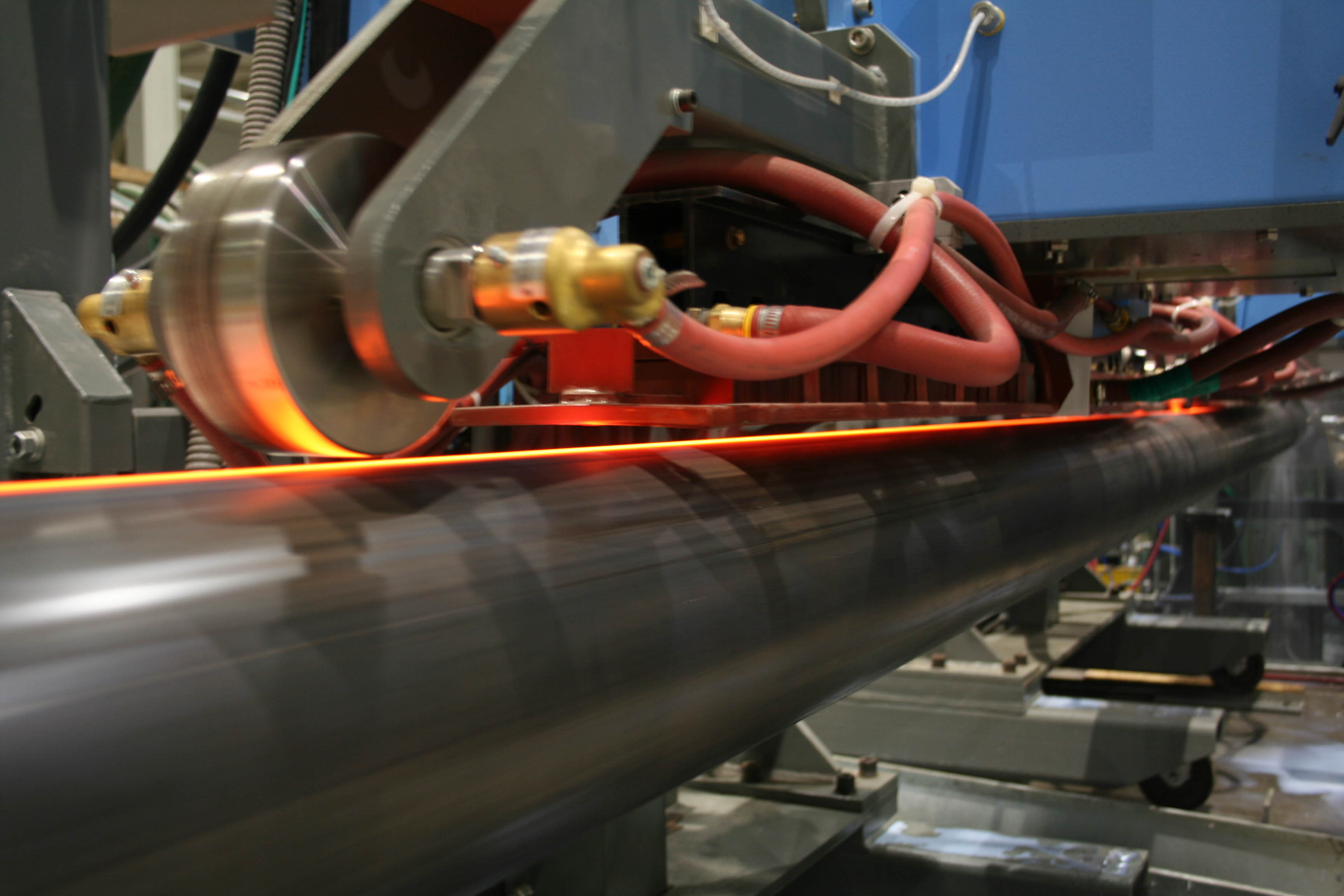

Thermatool™ in-line Seam Annealing / Normalizing equipment is designed to effectively Post Weld Heat Treat (PWHT) HF welded tube and pipe across a wide range of product diameters and wall thicknesses. To provide rigorous quality control and to ensure process repeatability, Thermatool® Seam Annealers are available with closed loop temperature control and real-time temperature monitoring. Thermatool™ Seam Annealers benefit customers producing API® products meeting 5L, 5CT, and material grades P110, L80, N80, X80, X100 specifications by ensuring no untempered martensite remains in the weld Heat Affected Zone (HAZ).

Powered by VIP™ Series Power Supplies, Thermatool™ Seam Annealers offer the most comprehensive automation and control package available to mill operators today. Teach and learn automation provides operators an interface for precise inductor positioning for each product diameter. Complemented by SmartAnneal™ software and SeamScan™ software, Thermatool™ Seam Annealers will respond to changing mill conditions including rotating seams and changing heat characteristics. This control ensures that all products meet the strictest application requirements.

In addition to standard tube and pipe applications, Thermatool™ Seam Annealers can be fit to spiral products, engineered structural sections, and custom tubular profiles.

Features

- High 92% efficiency/0.95 input power factor for all conditions

- Mill-mounted carriage assembly for precise positioning of the inductor

- Quick-lift mechanism to rapidly raise the inductor from the pipe, away from any open seam conditions

- Automated seam-tracking capability option

- Tube containment for small diameter product

- Independent free-moving carriages allow simple off-line maintenance

- Single and dual inductor configurations available to meet wide variety of applications

Tech Specs

Power output: 200kW to 3000kW

Operating frequency: 0.5kHz, 1kHz, 3kHz, or 6kHz as required