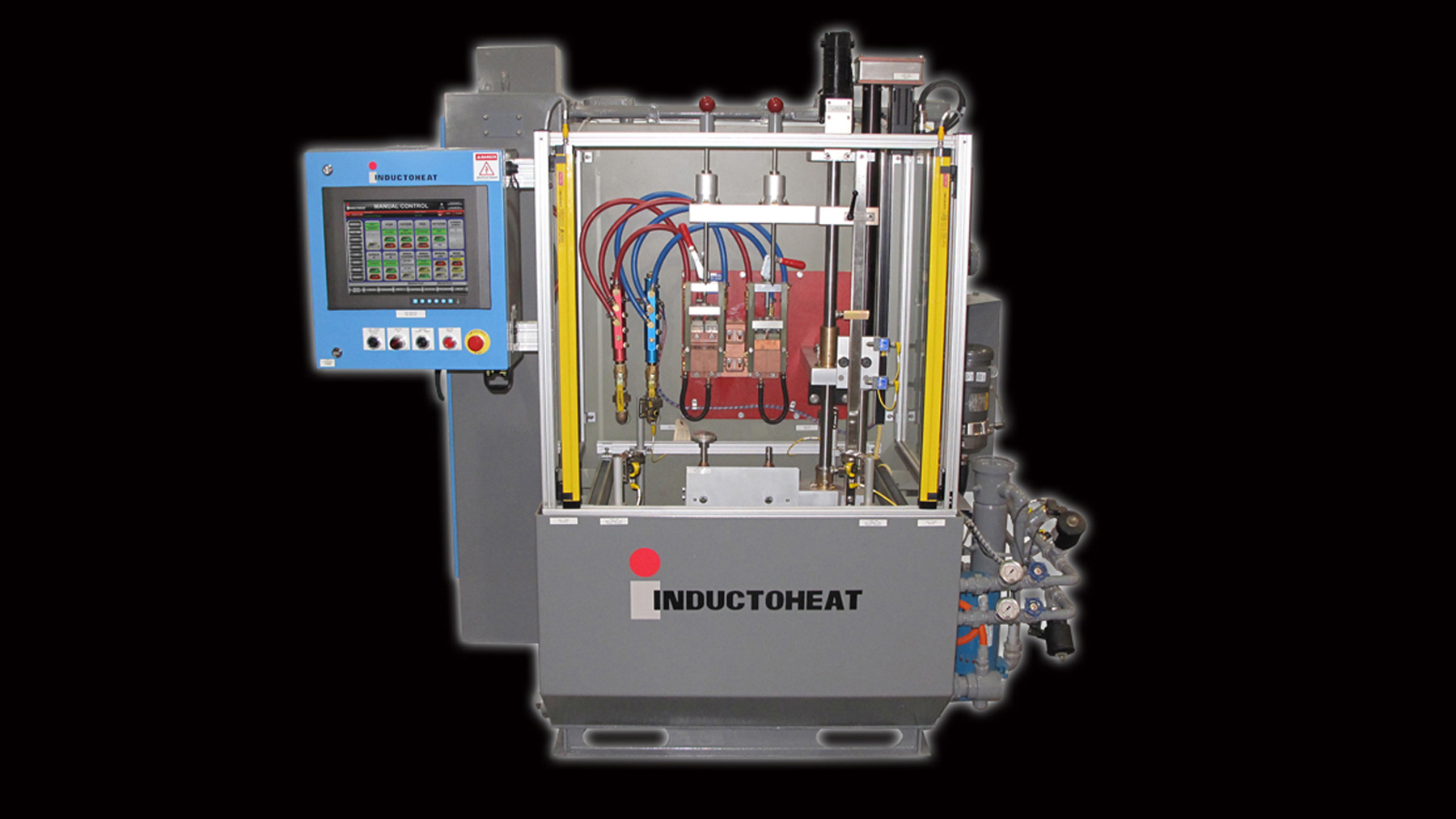

Statiscan™ II Modular Scanning System

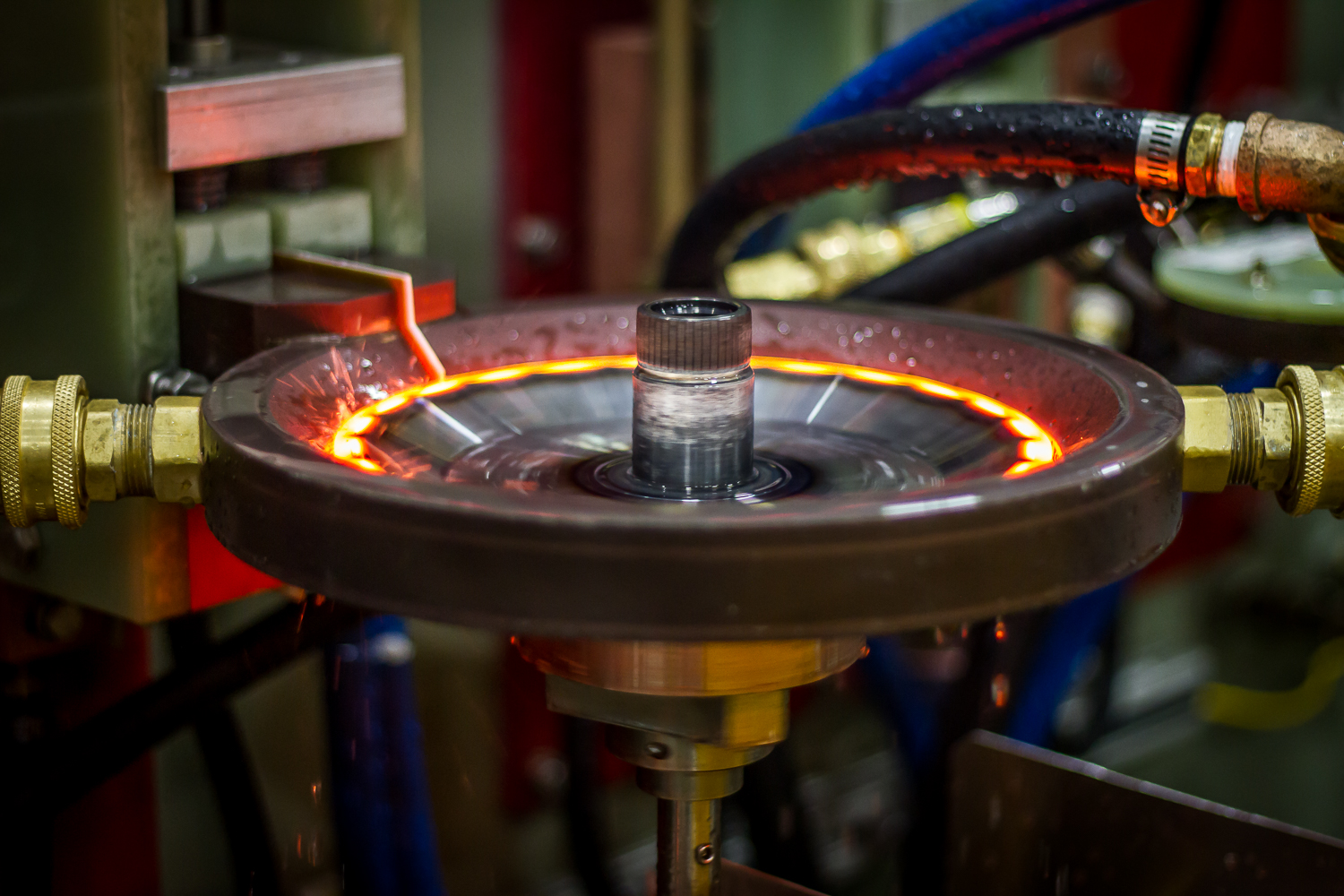

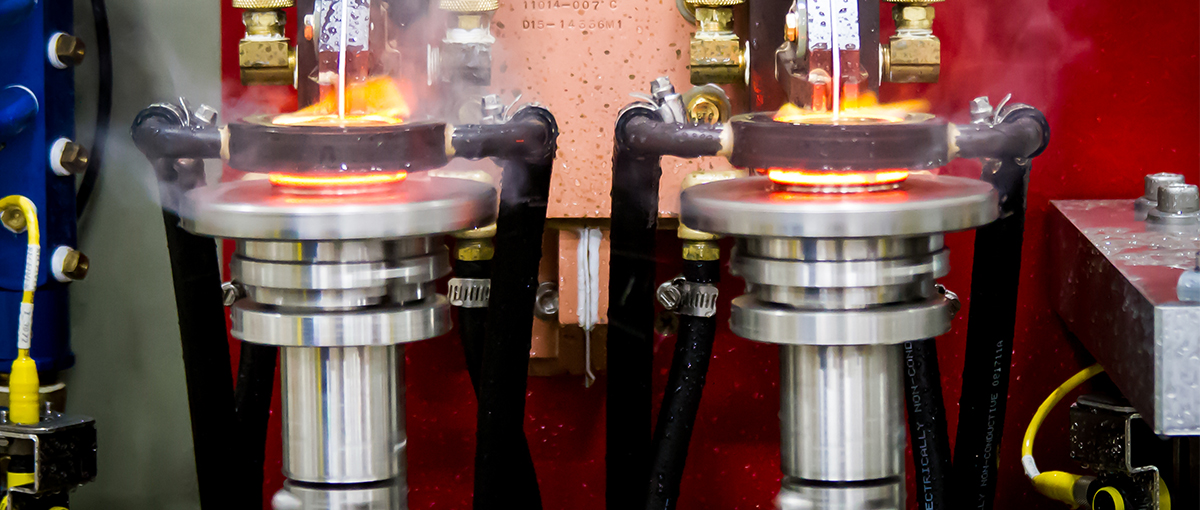

The Statiscan™ II modular scanning system is a unitized vertical hardening system with two standard scanning spindles. This platform is designed for medium duty heat treating and tempering of various parts and applications. This flexible machine can be configured for multiple heat treating operations such as; scan, single-shot, lift/rotate and linear transfer.

Features

- Two spindles to process multiple parts simultaneously

- Scans part lengths of 30 in., with maximum scan heated length of up to 24 in. on standard model

- Self-contained, compact design for minimal floor space and ideal for work cell

- Different power ratings and frequency ranges available for application matched precision hardening

- User-friendly controls simplify set-up, changeover and diagnostics

- Enclosed water cooling and quench recirculation system with filtration for quieter operation

- Built to machine tool standards for reliable performance

- Simple utility connection for fast installation and relocation

Tech Specs

| Standard Power Ratings | 50-300 kW @ 10-200 kHz | |

| Dimensions | 84” (2134) W X 74” (1880 mm) D X 98” (2489 mm) H | |

| Tower Span Length | 28.5” (724 mm) | |

| Maximum Part Length | 27” (686 mm) | |

| Scanning Speed (Max)/sec | 4”/sec | |

| Work piece Capacity/Spindle | 22 lbs. (10 kg/spindle) | |

| Spindle Center Spacing | 8″ (203 mm) | |

| Height Tower Up | 98″ (2489 mm) | |

| Height Tower Down | 88″ (2235 mm) | |

| Standard Controls | Standard PLC with HMI interface with virtually unlimited program recipe storage | |

| Cooling system | Closed-loop nonferrous reservoir, heat exchanger, and recirculating system with centrifugal pump | |

Accessories

- High pressure coil recirculating pump system

- Insta-Change coil adapter

- Servo rotation motors for precision movement

- Interchange bus adapter

- Process monitoring signature package

- Process data archiving

- Pneumatic load assist vees

- Pneumatic upper centers

- Automatic lubrication system

- Quench filtration upgrade

- Robotic interlock package

- 6 Axis 20kg robot